| Type | Product | Application | Characteristics | Use |

|---|---|---|---|---|

| Paint waterproofing agent | Inorganic elastic film waterproofing agent | Waterproof and insect-proof adhesive crack repair |

Synthetic and natural rubber packs are products specially processed from polymer synthetic resins. Excellent impact resistance, bending resistance, and chemical resistance. Excellent adhesion to wet surfaces and salt resistance. |

General and special waterproofing bridge surfaces and water, sewage, and wastewater treatment plants. Multi-purpose waterproofing for engineering and architecture. ship deck covering. |

| Mineral composite waterproofing agent |

Waterproof dustproof rustproof |

A product containing epoxy resin and tar. Solvent type, non-solvent type, dry, wettable, low temperature curing, high temperature curing. Excellent water resistance, chemical resistance, and adhesion. |

For general waterproofing. General lining flooring, concrete, steel coating. filler. |

|

| Penetrability | Penetrating waterproofing agent |

Penetration Waterproof |

Blend of liquid matrix mclaxn and elastic pouza. Excellent for strong water pressure due to coating film. Impact resistance, chemical resistance. |

For general and special waterproofing. Concrete structures with a lot of vibration. Civil engineering, construction, multipurpose waterproofing. |

| Permeable film powder waterproofing agent |

Waterproof Insect repellent |

Water-resistant, impact-resistant elastic powder. |

Civil engineering, architectural waterproofing. Waterproofing admixture for concrete coating film. |

|

| Rubber resin type | Mortar waterproofing agent |

Adhesive Reinforcement |

Excellent compressive strength, impact resistance, excellent adhesion to wet surfaces. |

Waterproof mortar agent Reinforcement agent for concrete mortar. |

| Penetrating water repellent |

Waterproof Insect repellent |

Water-based, oil-based. Low viscosity (oily), medium viscosity, high viscosity (water-based) |

||

| Concrete waterproofing agent | Concrete waterproofing agent |

Waterproof Insect repellent |

Impact resistance Excellent compressive strength |

Building facility concrete waterproofing Ready-mixed concrete pouring |

| Flooring | Flooring |

Waterproof Insect repellent |

Impact resistance, chemical resistance, wear resistance. Excellent heat resistance. A good color. |

Office floor. Parking lot, factory and other flooring materials. |

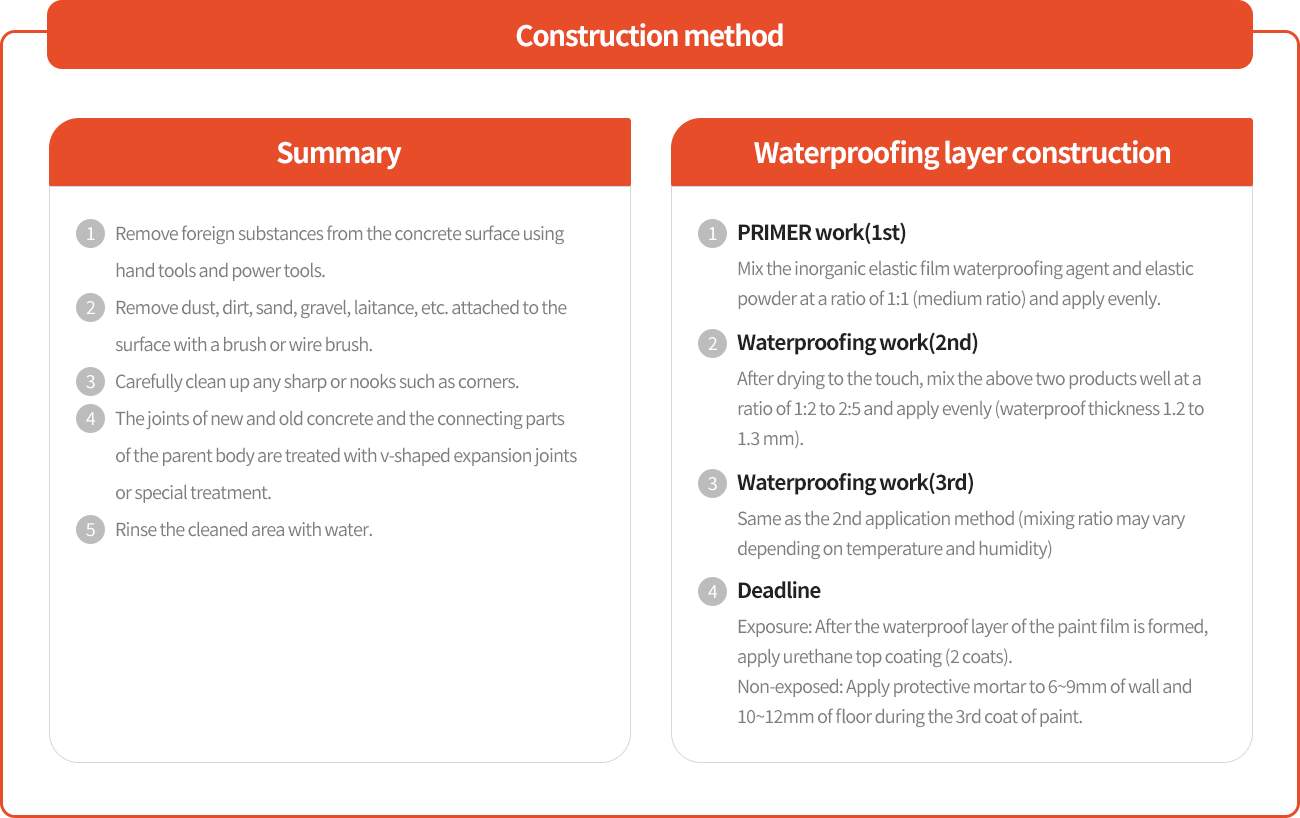

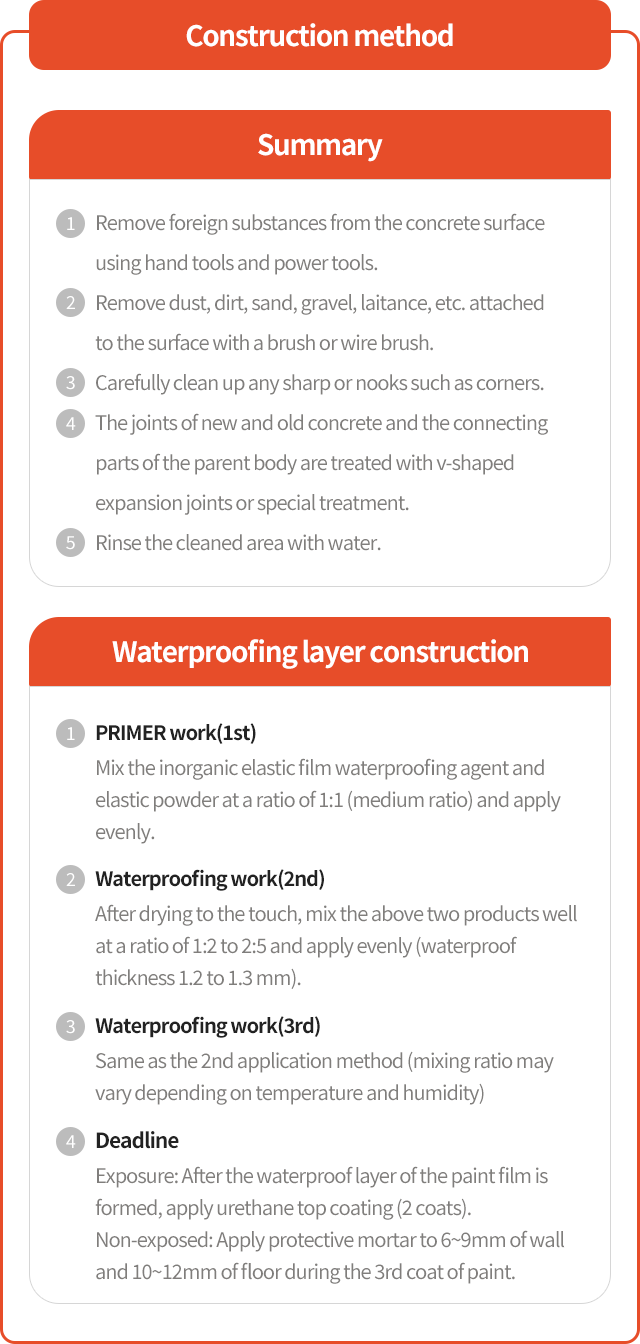

It is a specially processed emulsion product of polymer synthetic resin and natural rubber liquid. When mixed with elastic powder (penetration film powder waterproofing agent), it is a rubber cement-ified waterproofing agent that exhibits strong adhesion and waterproofing power.

Characteristics

- continuous waterproof layer on elastic rubber cement without seamlessness is obtained.

- Easy to work with as it hardens at room temperature.

- Because it is in the form of a water-soluble emulsion, it is possible to work even on wet surfaces.

- Strong cement alkalinity and affinity.(ph9.5~10)

- It is an elastic material that is strong even against minute cracks in the structure and has excellent bending properties.

- Resistant to temperature changes, excellent durability and weather resistance. (-60°C~550°C)

- Excellent adhesion.

- The construction method is simple and the curing time (4-5 hours, based on rooftop) is fast, shortening the construction period.

- No toxicity from fire or solvents.

Use

- Multi-purpose waterproofing of civil structures such as bridges, salt-resistance (coast), dams, ports, tunnels, subways, water supply, sewage, wastewater treatment plants, basements, rooftops, swimming pools, water tanks, septic tanks, and interior and exterior walls of basements.

- Binding agent for concrete cracks and leaks

- Reinforcement agent for concrete mortar.

- Chemical-resistant floor lining agent.

- Waterproofing of concrete structures subject to a lot of vibration (power plants, substations, factory machine rooms, etc.)

- Ship deck covering.

| Name Item |

Adhesion strength N/㎠ ( Kg f/㎠ ) |

Resistance to splitting | Absorption amount | Tensile performance |

Tensile strength N/㎠ ( Kg f/㎠ ) |

Permeability resistance | |

|---|---|---|---|---|---|---|---|

| 24 hours | Tensile strength | Elongation rate(%) |

30N/㎠ ( 3.1Kg f/㎠ ) |

||||

| Material Requirements | 100(10.2) or more | There should be no fine marks on the surface of the waterproof layer. | 2.0 or less | 100(10.2 or more) | 50 or more | 50(5.1) | Will not permeate under water pressure |

| Division Product | Unit | Required amount | Note |

|---|---|---|---|

| Inorganic elastic film waterproofing agent | ℓ | 1.8 | 3-times work |

| Permeable film powder waterproofing agent | kg | 3.6~4.5 | Based on 3m/m |

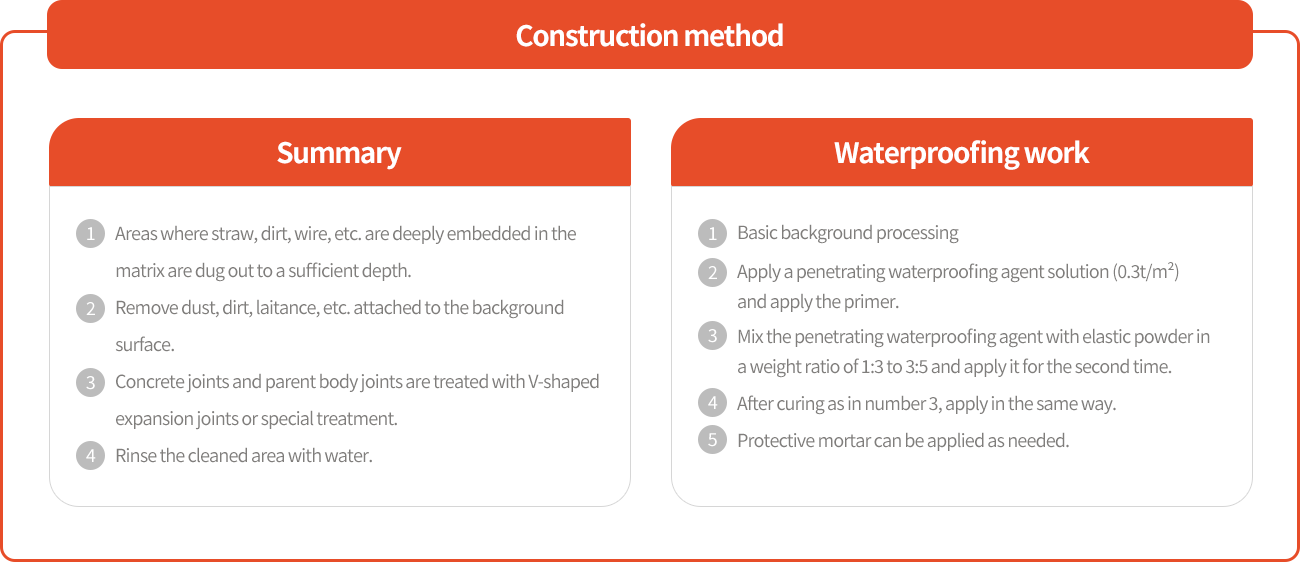

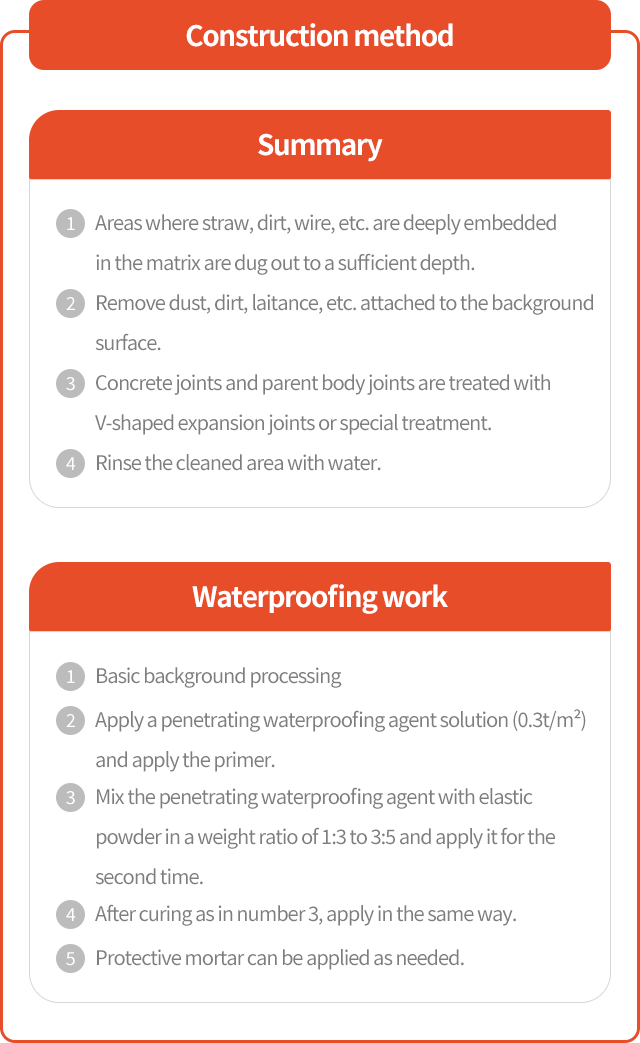

It is a product made by specially processing high molecular synthetic resin and turning it into a melt zone. When mixed with elastic powder, it exhibits strong adhesion and waterproofing power.

Characteristics

- 1 Excellent adhesion due to polymer synthetic resin emulsion.

- 2 It can withstand strong water pressure through a combination of penetration waterproofing and resin-mixed mortar.

- 3 Because it is in the form of a water-soluble emulsion, it can be used even on wet surfaces.

- 4 It has a rust-prevention effect, so metal fittings do not corrode.

- 5 Construction costs are reduced as construction is simple and curing time is fast.

- 6 No toxicity from fire or solvents.

Use

- 1 Water, sewage and wastewater treatment plants

- 2 Subways, pits, water tanks, septic tanks, and other places with high water pressure

- 3 Concrete structures (e.g. power plants, substations, factory machine rooms)

| Sample Items | Adhesion strength | Compressive strength | Absorption amount | Resistance to splitting |

|---|---|---|---|---|

| Siliceous system | 100 | 1000 | 2 | Fine branching |

| Powdered coating agent | (10.2)or more | (102)or more | or less | None |

It is an elastic powder that is used by mixing with various other materials and has the effect of increasing the adhesion of materials.

Characteristics

- 1 Water-resistant and impact-resistant elastic powder coating agent

Use

- 1 Civil engineering, construction, concrete coating waterproofing powder

According to specifications

It is a type of thermosetting resin that contains two or more epoxy groups in the molecule. The polymer mixed with tar and other chemicals is an organic compound that changes into a multi-purpose resin with exceptional hardness at room temperature or at elevated temperature by adding a hardener, and has various uses such as a protective coating material or adhesive. It is a product that demonstrates special properties for a wide range of applications, including insulation, adhesion, and F.R.P., including crack reinforcement index and waterproofing of water and sewage wastewater treatment plants, factory facilities, bridges, tunnel embankments, dams, coasts, ports, steel structures, ships, and bridge construction structures.

Characteristics

- Excellent adhesion to metal, stone, and other materials.

- Excellent mechanical properties such as flexibility, impact resistance,and bending resistance.

- Excellent chemical integrity (chemical resistance).

- Excellent insulation and heat resistance.

Use

- Water, sewage, wastewater treatment plant

- Swimming pool, water tank (water tank) waterproofing and protection

- Concrete mortar, waterproofing and anti-corrosion of metal structures

- Waterproofing and prevention of sewage treatment plants, water purification plants, etc.

- Vehicle, aircraft and ship deck covering agent

| Product Thickness | Mineral composite waterproofing agent - H | Mineral composite waterproofing agent - S | ||

|---|---|---|---|---|

| Base material(A) | Hardener(B) | Base material(A) | Hardener(B) | |

| Exterior | Color | Light yellow brown | Black Paste | Light yellow brown |

| Viscosity (C.P.S) | 11.000~14.000 | 15.000~30.000 | 9.000~12.000 | 1.500~3.000 |

| Specific gravity | 1.17 | 1.03 | 1.42 | 1.03 |

| Mixing ratio | 4:01 | 5.01 | ||

| Usage time | 1.5~2 hours | Mixed liquid | Viscosity (25℃) -3.000 | |

| Touch drying time | 4~5 hours | Usage time -50~60 min | ||

| Complete drying time | 1.17 | Touch drying time -6 hours | ||

| Painting method | Rollers, brushes and sprays | Curing time -24 hours | ||

※ The mixing ratio of materials used in this specification may be changed without prior notice to improve quality.

-

1

Mineral composite waterproofing agent -H(Color)

Since it is non-solvent, it does not require caution with toxic gases or fire, but skin contact should be avoided as much as possible.

-

2

Mineral composite waterproofing agent -S(Tar)

Because it is oil-based, care must be taken against toxic gases or fire, avoid skin contact as much as possible, and be installed by a technician with extensive experience in epoxy waterproofing.

※ In particular, a solvent-free (black) product that does not contain tar can be used.

※ In the case of water-soluble epoxy, no precautions such as toxic gases or fire are required, but skin contact should be avoided as much as possible.

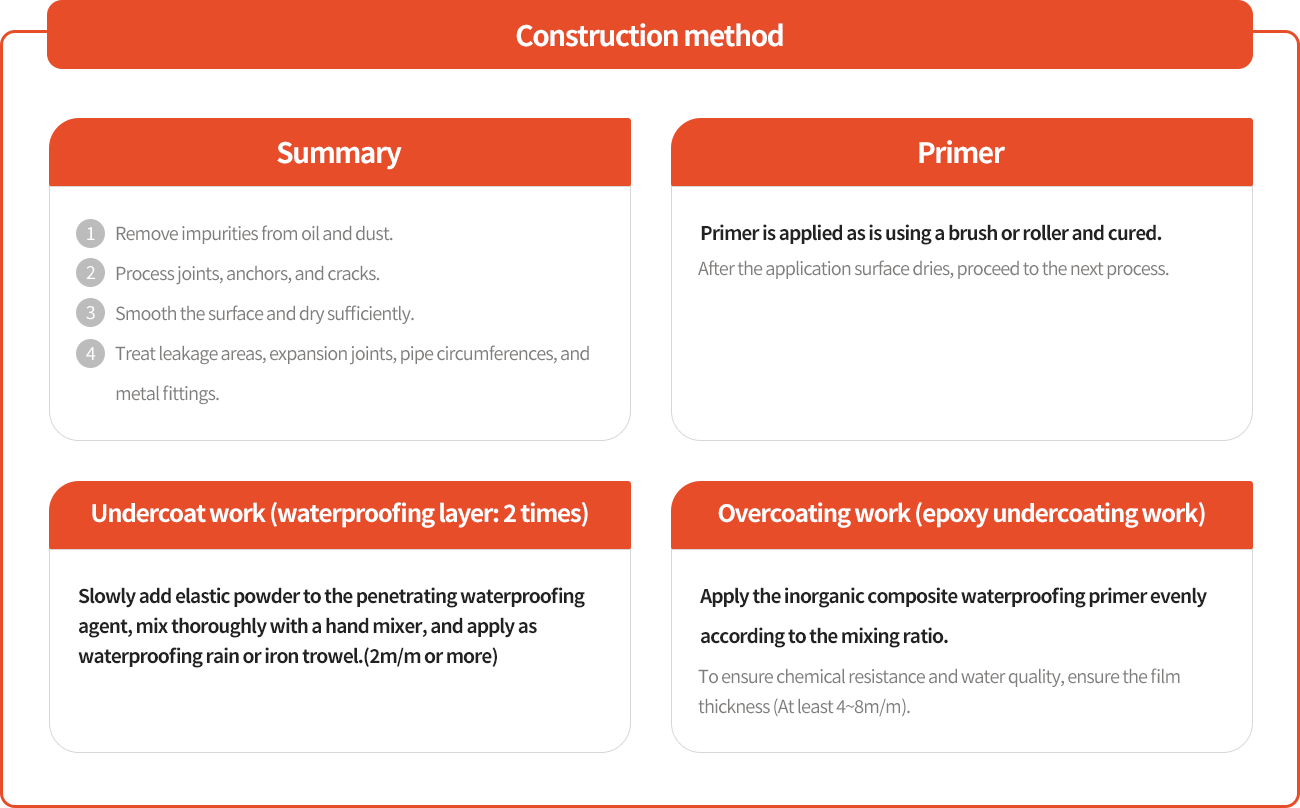

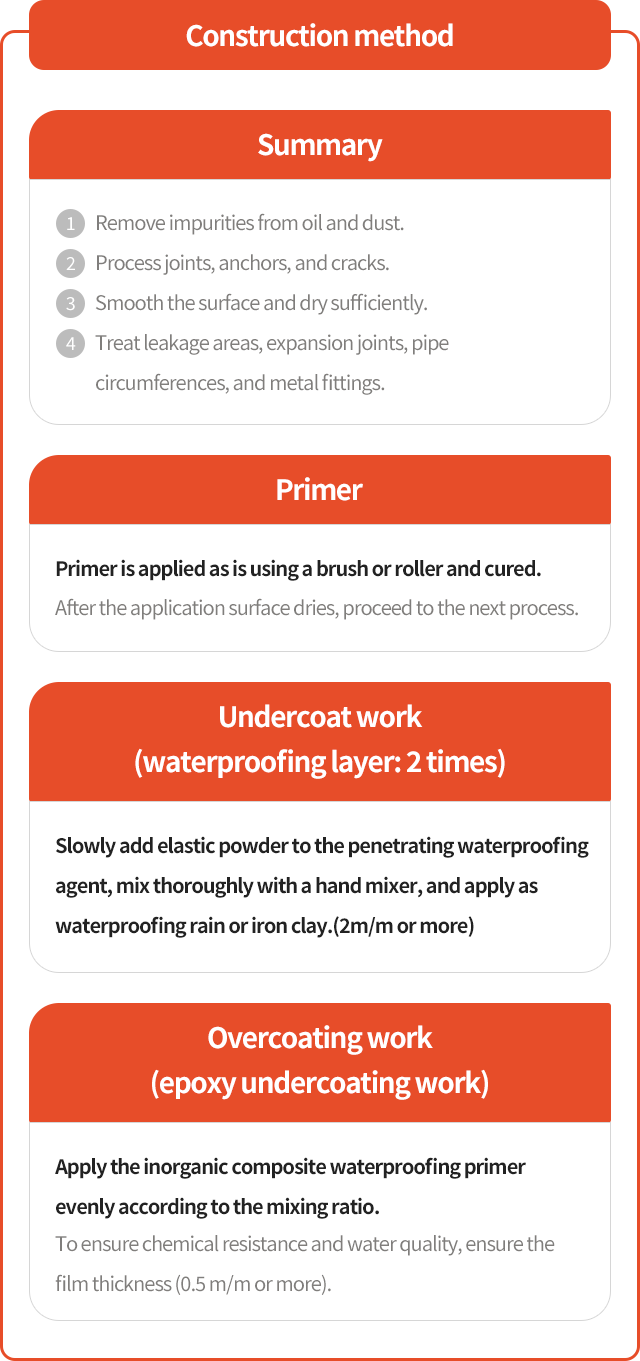

① Remove impurities from oil and dust. ② Treat joints, anchors, and cracked areas.

| Division Product | Unit | Quantity | Note |

|---|---|---|---|

| Penetrating waterproofing agent | L | 1.0 | Waterproof layer 2m/m or more |

| Permeable film powder waterproofing agent | kg | 3.0 | Waterproof layer |

| Primer | L | 0.3 | Waterproof layer |

| Mineral composite waterproofing agent-H(Color) | L | 0.8 | Waterproof layer 0.5m/m |

| Mineral composite waterproofing agent | L | 0.8 | Waterproof layer 0.5m/m |

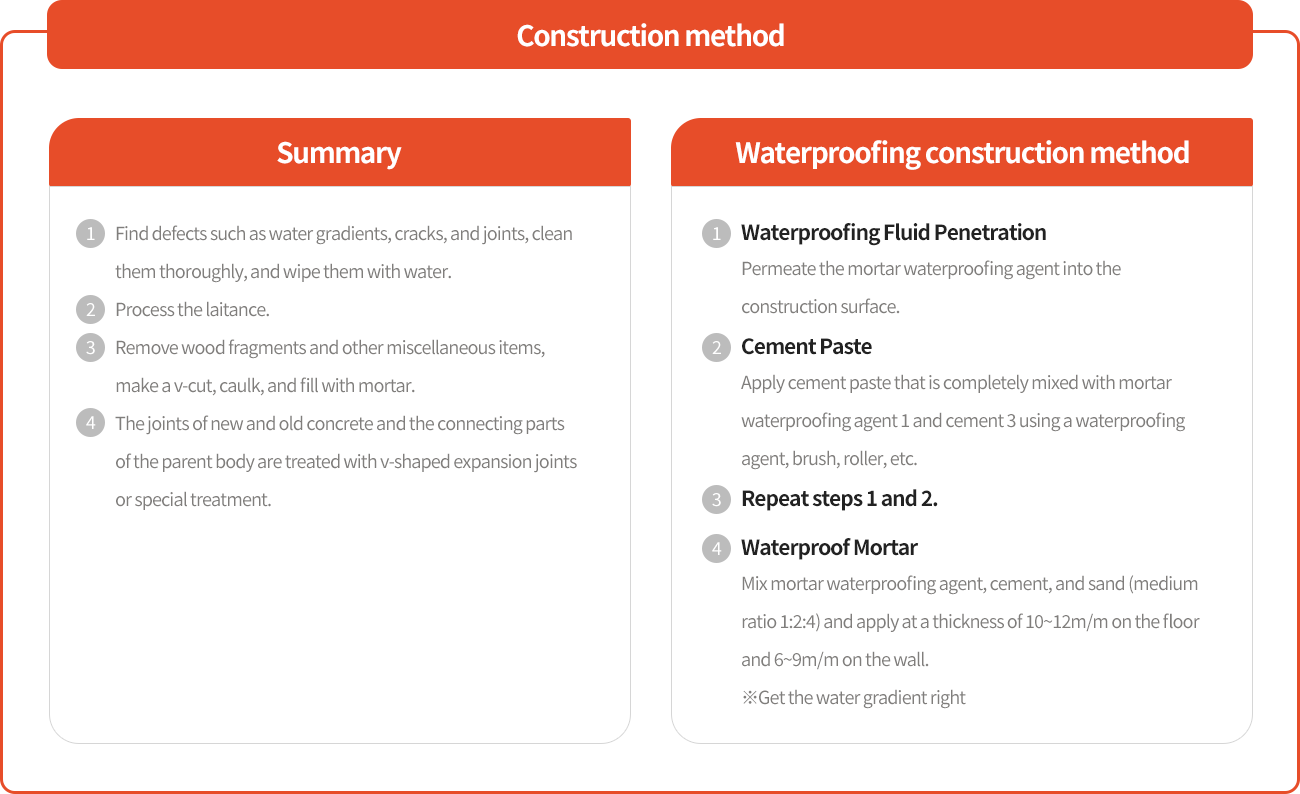

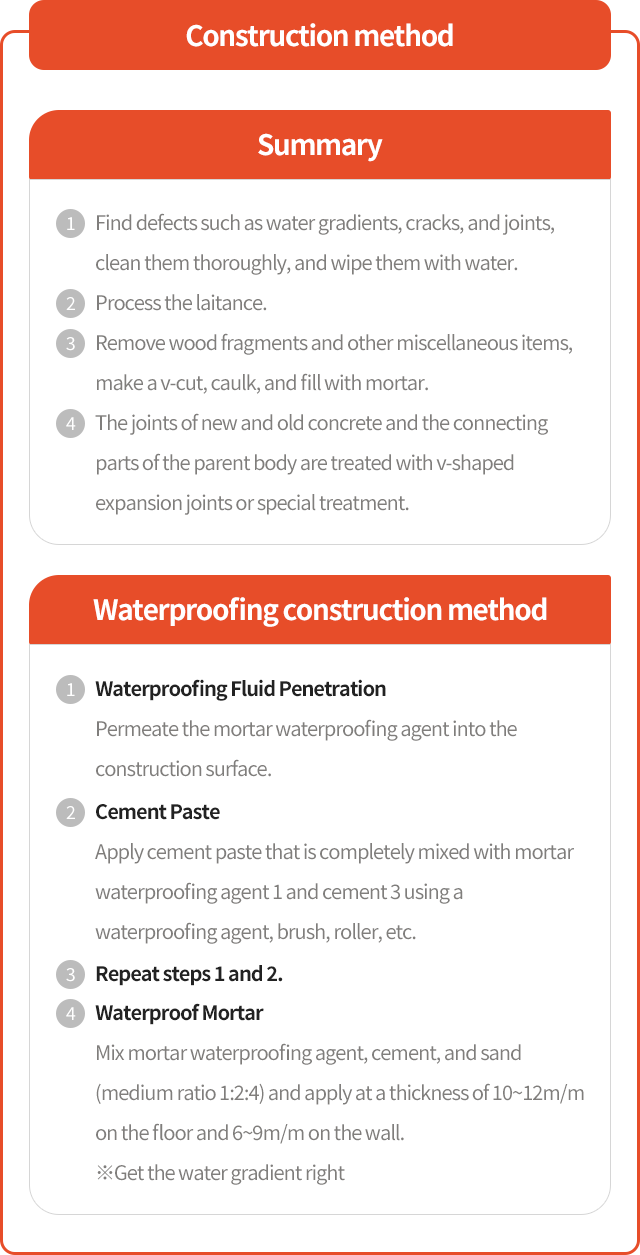

It is a waterproofing agent that creates a watertight layer by combining the ingredients contained in cement with a polymer to provide a waterproofing effect. Mortar waterproofing agent is an ideal mortar polymer waterproofing agent that has excellent performance and reliability through an easy-to-install waterproofing method.

Characteristics

- It is similar to plastering work that uses cement and sand as main materials.

- Construction is possible even if the background is wet or contains moisture before construction.

- Resistant to vibration.

- Excellent bonding strength with cement.

- Excellent elasticity and flexibility.

Use

- Basement, rooftop, interior wall, exterior wall waterproofing

- Water tank, dam, bathroom, swimming pool waterproofing

- Ship Deck Covering

- Waterproofing of cracks and leaks in concrete mortar

| Product Division | Unit | Required Amount | Note |

|---|---|---|---|

| Mortar Waterproofing Agent | L | 1.2 | Apply waterproofing solution |

| Cement | kg | 3.0 | Includes 2 times (0.2L) |

| Product Division | Unit | Required Amount | Note |

|---|---|---|---|

| Mortar Waterproofing Agent | L | 1.4 | 9~12m/m |

| Cement | kg | 2.8 | |

| Sand | kg | 5.6 |

It is a waterproofing agent that completely solves problems such as freezing, falling, water leakage, rotting, cracking, and efflorescence that occur due to moisture absorption in interior and exterior materials of buildings, and is both water-repellent and breathable. It is the most ideal product to preserve the original color of a building.

Characteristics

- Completely permeable and no film surface formation occurs.

- Prevents falling off, freezing, and rotting due to moisture.

- Weathering is prevented.

- Prevents dirt adhesion and capillary penetration.

- Because it can be mixed with paint, it has excellent water-repellent paint effect.

- Strong water repellency resistance prevents whitening.

- Excellent chemical resistance.

Use

- Cement mortar surface waterproofing

- Natural stone, wood

- Tile, straight board, gypsum board

- Brick concrete surface waterproofing

- Tile meshes

- Other waterproof

-

1

Basic work

Remove foreign substances such as dust, dirt, oil, and efflorescence and dry thoroughly.

-

2

Spraying work

Apply the penetrating water repellent 2 to 3 times using a spray, brush, or roller.

| Number of times | 1 | 2 | 3 |

|---|---|---|---|

| Required amount(ℓ) | 0.25 | 0.2 | 0.2 |

| Division | Hours | ||

|---|---|---|---|

| 48hr | 168hr | 720hr | |

| When treating penetrating water repellent | 0.18kg | 0.56g | 2.85g |

| When not processed | 7.3g | 7.9g | 10g |

| 15 days | 30 days | 120 days | 300 days | |

|---|---|---|---|---|

| When treating penetrating water repellent | A state where water droplets form like dew | Same as left | The state of water droplets forming and flowing | Same as left |

| Item | Recognition | Weather resistance | Waterproof | Vaporous | Bleaching phenomenon |

|---|---|---|---|---|---|

| Standard | There will be no precipitation separation or solidification phenomenon when stored for 6 months. | Absorption rate less than 5% for 100 hours | Moisture rate less than 2% | 50% or more | Must not exist |

| Conclusion | Clear | Clear | Clear | Clear | Clear |

| Test methods | KSL 2003 | ||||

When used together with ready-mixed concrete, it is an ideal product that increases the strength of concrete, improves the water retention and waterproofing effects of cement, and prevents condensation.

Characteristics

- It is resistant to temperature changes and has excellent durability and weather resistance.

- Excellent waterproof and insect repellent properties.

- Excellent heat resistance and sound absorption.

- Excellent impact resistance and bending resistance.

Use

- When pouring concrete for basement floors, rooftop floors, walls, etc.,mix it with ready-mixed concrete..

- 1 Use a concrete waterproofing agent.

- 2 Use 1.8L of concrete waterproofing agent for 6㎥ of ready-mixed concrete.

- 3 The concrete waterproofing agent is poured into ready-mixed concrete and rotated for at least 15 to 30 minutes before pouring.

※ Depending on site conditions, Latexyl #100H concentrate can be used.

It is a composite product made with additives based on advanced synthetic resin (MMA). This product has excellent mechanical strength and abrasion resistance, so it does not raise dust, and the concrete below the floor is destroyed before the main floor when subjected to the impact of an excessive load,and the maximum compression, torsion, and maximum elongation until failure are much greater than those of concrete. It is an economical and innovative flooring agent that is easy to install and cures quickly.

Characteristics

- Excellent chemical and oil resistance.

- Excellent mechanical strength, curing time is much faster than existing products(2~3 hours)

- There are no seams and no dust is generated. Walking is possible 2-3 hours after work.

- The construction method is simple, the construction period is short, and the construction cost is low, making it economical. Easy to repair in case of damage.

Use

- Parking lot

- Flooring material for spaces that avoid dust from electronics, electrical machinery, food, etc.

- Flooring for factories, offices, warehouses, buildings, etc.

- Plating, dyeing, pulp, rayon, pharmaceutical plants, etc. in chemical plants that use acids, such as machines, foundation walls, and flooring agents for acid-resistant construction.

- 1 Avoid working on basement floors or in humid places with poor ventilation.

- 2 Avoid work, even indoor work, as much as possible in rainy weather or under climate conditions with high humidity (over 70-80%).

- 3 When constructing a wet area, completely dry it with a torch lamp before performing the work.

| Type Material name | DFP 2000S | DFP 2000W |

|---|---|---|

| 3 times | 4 times | |

| Inorganic elastic film waterproofing agent | 1L | |

| Elastic powder | 2.0~2.kg | |

| Floor primer | 0.3L | 0.3L |

| Flooring | 0.4L | 0.4L |

| Diluent | Appropriate amount | Appropriate amount |